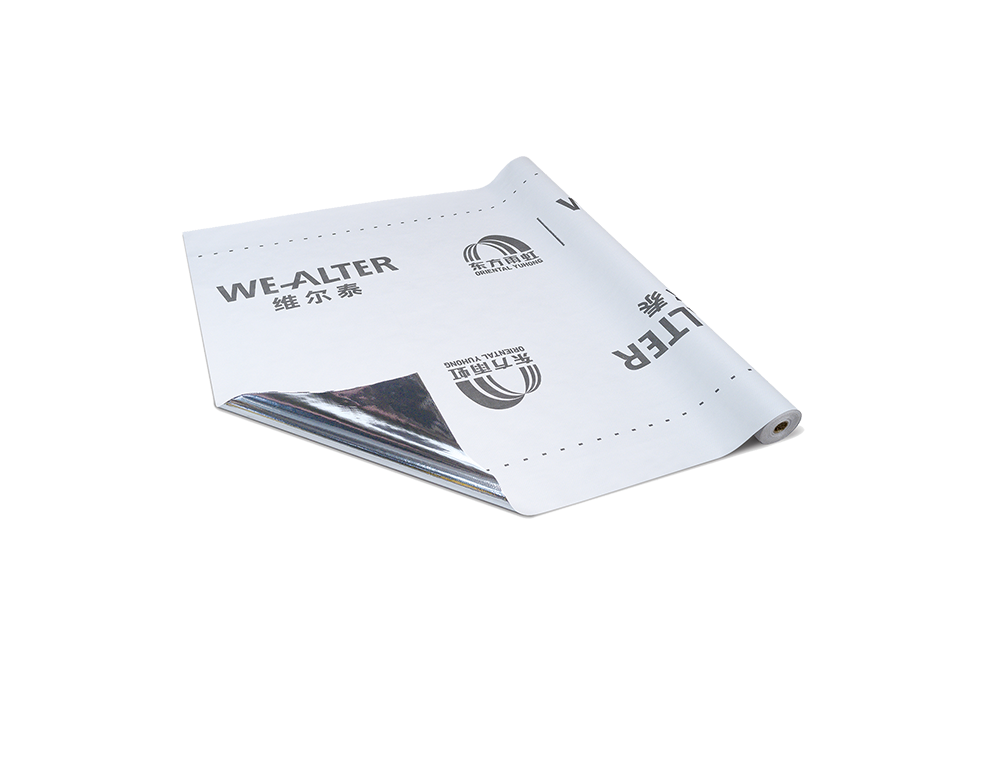

Wealter enhanced moistureproof vapor barrier membrane is made of reflective aluminized membrane, high-strength woven fabric and polypropylene non-woven fabric compounded by a special process. The thickness is 0.3mm, and the overall color is white. The reflective smooth surface of the non-woven fabric is rough, which is able to play a role in isolating water vapor and blocking visible water, forming a continuous protective layer for the insulation layer.

Features:

With thermal radiation reflection function: The reflective layer of aluminum plated membrane brings additional thermal radiation reflection function to the overall membrane material, allowing the membrane material to isolate water vapor while reflecting most of the thermal radiation received by the enclosure structure, greatly improving the energy-saving effect of the insulation system and bringing cost reduction and efficiency benefits to the use of buildings.

High strength: The longitudinal and transverse tensile strength, as well as the tearing strength of the nail bar, far exceed that of conventional polyethylene membrane, which can well cope with pulling, foreign object puncture, and scratching during use, making the water vapor protection layer more durable and safe.

Low water vapor permeability: It has excellent water vapor insulation performance, with a water vapor permeability of ≤ 1g/㎡·24h (tested according to GB17146), which can greatly reduce the water vapor that enters into the insulation layer under the effect of temperature difference.

Impermeability: It has certain waterproof performance, with an impermeability of ≥2500mm, and a 2-hour impermeability (tested according to GB/T328.10-2007), which can improve the waterproof function of the whole enclosure structure system.

Aging resistance: The raw material ratio and selection process have been specially designed to improve the aging resistance, which can well adapt to the application scenarios such as metal roofs with large temperature changes.

Product Description

Product Description Application Scope

Application Scope